Manufacturing

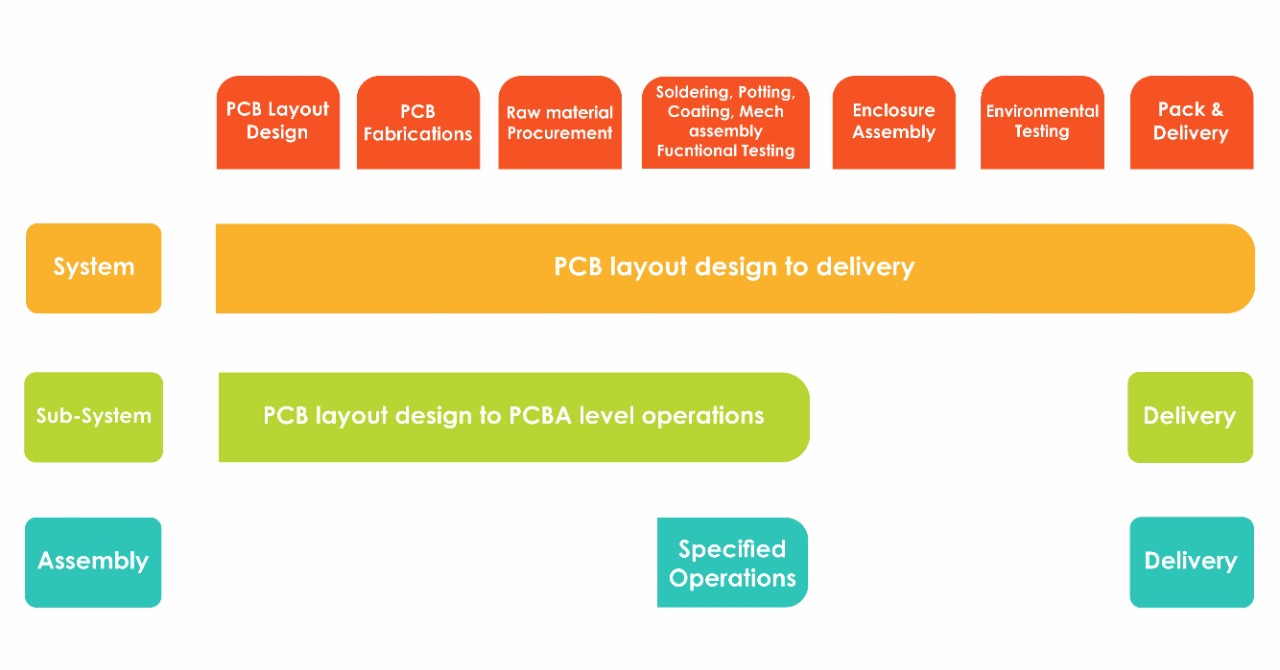

Anuvega provides the manufacturing services in the field of PCBA and Harness. Manufacturing services are provided in the form of Systems, Subsystems and Assembly. In Anuvega we provide the manufacturing services from raw material procurement to order delivery.

Manufacturing Capabilities

Anuvega provides you a single step solution in the area of PCBA manufacturing with all inhouse facilities in a hybrid method of manufacturing both automated and manual operations.

Anuvega provides you a single step solution in the area of PCBA manufacturing with all inhouse facilities in a hybrid method of manufacturing both automated and manual operations.

Anuvega has the capability, experience and knowledge to Manufacture the Printed Circuit Board Assemblies (PCBA’s)

We have a good infrastructure and working environment with well-equipped machinery and well trained and certified manpower.

Complete shop floor is ESD grounded & Protected as per the ESD standard – ESD S20.20

We Manufacture PCBA’s for all three classes of electronic products: Class – 1, Class – 2 and Class – 3 Products. We manufacture PCB assemblies for all kinds of printed circuit boards like Rigid and flexible; layers from single to multiple; single sided and double sided.

Manufacture’s PCBA’s for all the three levels of manufacturing services: System, Sub-system and Assembly. From Surface Mount Technology, Potting, Conformal Coating to complete Box Build top level assemblies and Environmental Testing. We do offer Manufacturing services for NPI build along with regular repetitive orders of Mass and small quantities.

Manufacture’s PCBA’s for all the three levels of manufacturing services: System, Sub-system and Assembly. From Surface Mount Technology, Potting, Conformal Coating to complete Box Build top level assemblies and Environmental Testing. We do offer Manufacturing services for NPI build along with regular repetitive orders of Mass and small quantities.

Manufacture PCBA’s in compliance with various standards, as a default of IPC-A-610 (Acceptability of Electronic Assemblies) and other customer specified standards (if specified). Robust Manufacturing process we follow looks over the overall quality, productivity and safety of product.

We have various teams to make the manufacturing run.

- Product Engineering team that defines & stream line the process to achieve the adequate quality required for the product.

Industrial Engineering team to monitor the process and product cycle times in accordance to balance the line, measure the utilization and analyse the foreseen capacity and of machines, manpower requirement.

Industrial Engineering team to monitor the process and product cycle times in accordance to balance the line, measure the utilization and analyse the foreseen capacity and of machines, manpower requirement.- Equipment & Process team to setup the machine and process parameters defined for the production run along with regular and periodic maintenance of machines.

- Quality team to control and assure the quality compliance of product.

- Production & Planning team to run the line with efficient usage of machines with high productivity, minimal down & change over time with adequate quality for the product.

We make cross functions teams, to regularly monitor and solve product issues that continually improve the quality of products and processes.

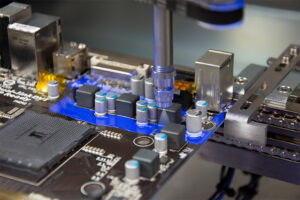

Surface mount Technology (SMT) is a fully automated with dedicated SMT manufacturing line from Baking to Reflow soldering until X-Ray including profiling at reflow stage.

Details and Capabilities of the installed machinery of SMT Line in the facility are tabled and figured below.

| Sl. No | Chamber-model | Specifications |

| 1 | ESPEC Hot oven- PH 202 | Ambient to 200°C |

| 2 | ESPEC Hot oven- PH 202 | Ambient to 200°C |

| Technical Capabilities | Specification |

| Machine Alignment Capability | @±12.5 pm |

| Core Cycle Time | 8 secs + process |

| Squeegee Pressure Mechanism | Software Controlled, motorised with closed loop feedback ± kg |

| Process | Specification |

| Print Method | Paste Roll Height Monitor |

| Stencil Positioning | Automatic loading incorporating squeegee drip tray |

| Vision & Verification | Specification |

| Hawk EyeⓇ | Paste on pad verification |

| Transport | Specification |

| Substrate Support | Vaccum tooling Capability Grid-Lok tooling |

| Component Range | Specification |

| Component Range | Chip from (01005), SOIC, PLCC, TSOP, QFP, BGA, flip chip, odd shape, surface-mount connectors, CSP, CCGA, Tantalum Chip (from 01005), SO28, SOT223, SOJ20, PLCC32, MELF, SOD. |

| Component Specification | Min: 0.4×0.2 mm (0.016″ × 0.008″) (01005) Max: 140×73×15 mm (5.51″ × 2.87″ × 0.59″) Max: Component weight: 140 g |

| Placement, Speed & Accuracy | Specifications |

| Rated speed | 24 000 CPH |

| Chip repeatability 3 (X, Y, Theta) | 30 µm. |

| Feeder Capacity | 128 |

- 12 Zone (9 heating; 3 Cooling)

- Built in KIC thermocouple

- External 7 channel SPS KIC thermal Profiler

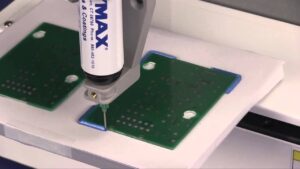

Operations other than SMT to be performed for the PCBA are performed at the backend. These process include:

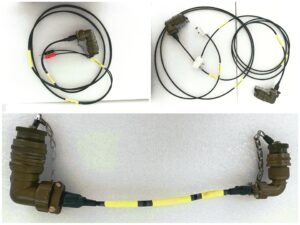

We make cable harnesses of all verities most demanded in the market. We have specialised and certified manpower with well-equipped facility.

We manufacture cable and wire harness in compliance with IPC/WHMA-A-620D (Requirements and Acceptance for Cable and Wire Harness Assemblies) standard or with customer specified standards (if applicable).

Manufacturing Cable and Wire Harness assembly with all the operations made according to scope of work defined.

Product Range

- Launcher Cable Harness

- Missile Cable Harness

- Electromechanical Cable harness

- PCBA bus bar Harness

- PCBA wire Harness

Some of the product photographs of the manufactured harnesses are displayed below